Precision component integration is crucial in numerous industries, demanding reliable and robust solutions. Overmolding presents a versatile approach to achieve this, offering significant advantages over traditional assembly methods. By encasing delicate components within a protective thermoplastic shell, overmolding enhances durability, minimizes stress points, and creates a seamless, unified structure. This process facilitates the creation of complex geometries and integrated features, streamlining design and manufacturing workflows.

- Numerous thermoplastic materials are available for overmolding, offering tailored properties to meet specific application requirements.

- Overmolding processes can be customized to accommodate a wide range of component sizes and shapes.

- Advantages include improved shock absorption, reduced vibration, and enhanced electrical insulation.

Personalized Insert Molding Services for Enhanced Functionality

Achieving optimal functionality in your plastic products often requires a precise and versatile manufacturing process. That's where custom insert molding comes into play, offering producers a powerful solution to integrate integrated components seamlessly within molded parts. This technique involves embedding pre-made inserts—ranging from metal springs and electrical contacts to complex electronic circuitry—directly into the mold cavity during the molding process.

The result? Enhanced functionality, durability, and effectiveness in your final here products. Custom insert molding eliminates the need for distinct assembly steps, improving production time and costs. Whether you require resilient electrical connections, intricate mechanical components, or specialized functionalities, custom insert molding provides the versatility to meet your specific needs.

Expert Overmolding & Insert Molding Capabilities

Our sophisticated manufacturing facility is equipped to handle complex overmolding and insert molding projects. We leverage advanced machinery and qualified technicians to achieve precise alignment of components, resulting in durable and high-performance finished products.

We are proficient in working with a broad range of materials, including elastomers, to meet your specific design requirements. Our dedication to quality and precision ensures that every overmolded or inserted part satisfies industry standards.

Whether complexity of your project, our team is dedicated to providing you with superior service and dependable results.

Seamless Overmolding and Insert Molding: Delivering Exceptional Results

In the realm of manufacturing, achieving precision cohesion between diverse materials is paramount. This is where seamless overmolding and insert molding techniques emerge as powerful solutions, delivering unrivaled results for a wide range of applications.

Seamless overmolding involves encasing one material within another, creating a secure bond that enhances both the operational properties and aesthetic appeal of the final product. Insert molding, on the other hand, involves pre-existing components into a molded part, enabling the creation of complex assemblies with intricate functionalities.

- Strengths of seamless overmolding and insert molding include:

- Enhanced durability and impact resistance

- Minimized assembly time and costs

- Greater design flexibility and customization

- Superior product performance and reliability

Advanced Overmolding and Insert Molding Technologies

The realm of plastics manufacturing has witnessed remarkable developments in recent years, with advanced overmolding and insert molding technologies taking center stage. These methods enable manufacturers to produce complex, multi-material components with intricate designs and superior functionality. Overmolding involves applying a secondary layer of plastic onto an existing substrate, while insert molding encompasses embedding pre-determined inserts within the molten plastic during the molding process. Both techniques offer numerous benefits, including enhanced durability, improved aesthetics, and reduced assembly costs.

Applications for these advanced technologies are ubiquitous, spanning industries such as automotive, electronics, medical devices, and consumer goods. From rugged housings for electronic devices to intricate connectors for automobiles, overmolding and insert molding provide the accuracy required to meet demanding engineering specifications. As manufacturers continually strive to optimize product performance and reduce production costs, these technologies are poised to play an even more essential role in shaping the future of plastics manufacturing.

Our Team in Innovative Overmolding and Insert Molding

When seeking cutting-edge solutions for overmolding and insert molding, consider [Company Name]. We're dedicated to achieving exceptional results that surpass client expectations.

- We have a proven track record in diverse molding projects, and we always invest in the latest technologies to ensure industry-leading quality.

- We is to establish partnerships with our partners by offering personalized service, consistent results, and dedicated support during every stage of the process.

Get in touch to explore how we can partner with you on upcoming overmolding and insert molding project.

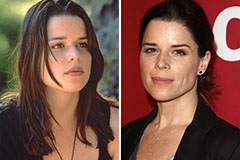

Neve Campbell Then & Now!

Neve Campbell Then & Now! Burke Ramsey Then & Now!

Burke Ramsey Then & Now! Tonya Harding Then & Now!

Tonya Harding Then & Now! Christy Canyon Then & Now!

Christy Canyon Then & Now! Sarah Michelle Gellar Then & Now!

Sarah Michelle Gellar Then & Now!